- Home

- >

- News

- >

- Technical News

- >

- Synthetic Fiber Cutting Blade

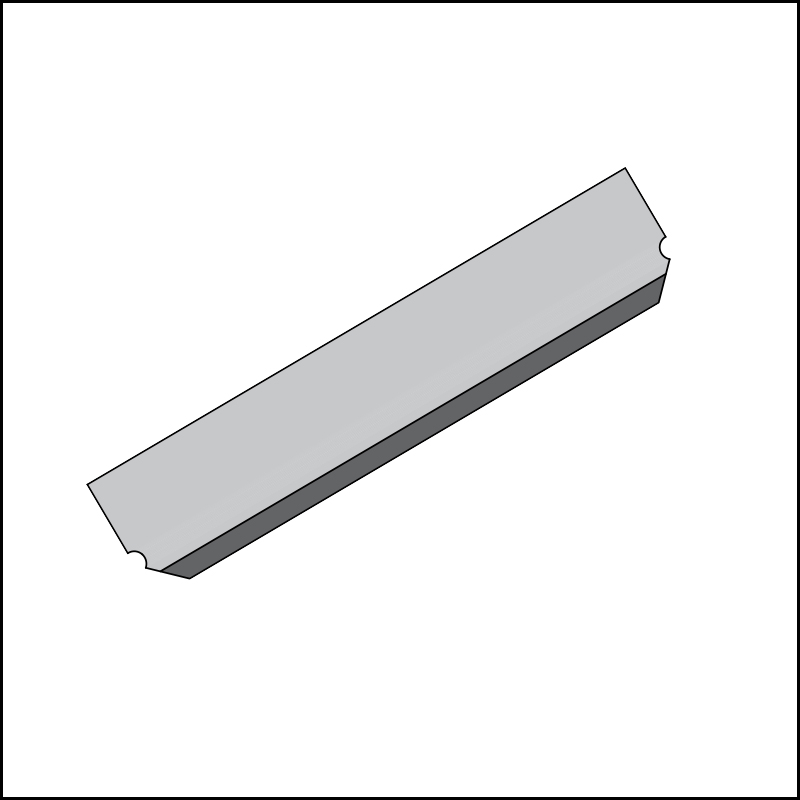

Synthetic Fiber Cutting Blade

Synthetic Fiber Cutting Blade: Precision Engineering for Recycled & Composite Applications

The Synthetic Fiber Cutting Blade is a technical marvel tailored to the rigors of modern industrial processing, with specialized optimizations for recycled synthetic fibers (PET, nylon) and advanced composite materials. Crafted from ultra-high-strength tungsten carbide with 10% cobalt binding, it delivers 700% longer service life than standard steel blades, resisting abrasion from contaminants in recycled fibers—such as dirt, dyes, and residual chemicals.

Engineered with a micro-serrated edge geometry and titanium carbonitride (TiCN) coating, the blade minimizes fiber fraying and adhesion, ensuring clean, burr-free cuts at speeds up to 2500 meters per minute. Its precision-ground finish maintains a cutting edge tolerance of ±0.3mm, critical for composite manufacturing where consistent fiber length directly impacts material strength.

For recycled fiber processing, anti-clog grooves and heat-resistant properties (up to 250℃) prevent downtime from resin buildup and high-speed friction. Compatible with automated cutting systems and modular machinery, this blade enhances productivity across textiles, nonwovens, and composite production lines. By combining premium materials, advanced coatings, and application-specific design, it sets the standard for reliability and efficiency in synthetic fiber cutting—reducing waste and lowering operational costs for industrial manufacturers worldwide.