- Home

- >

- News

- >

- Blade Technology Updates

- >

- How Thin Film 3-Hole Blades Revolutionize Advanced Manufacturing

How Thin Film 3-Hole Blades Revolutionize Advanced Manufacturing

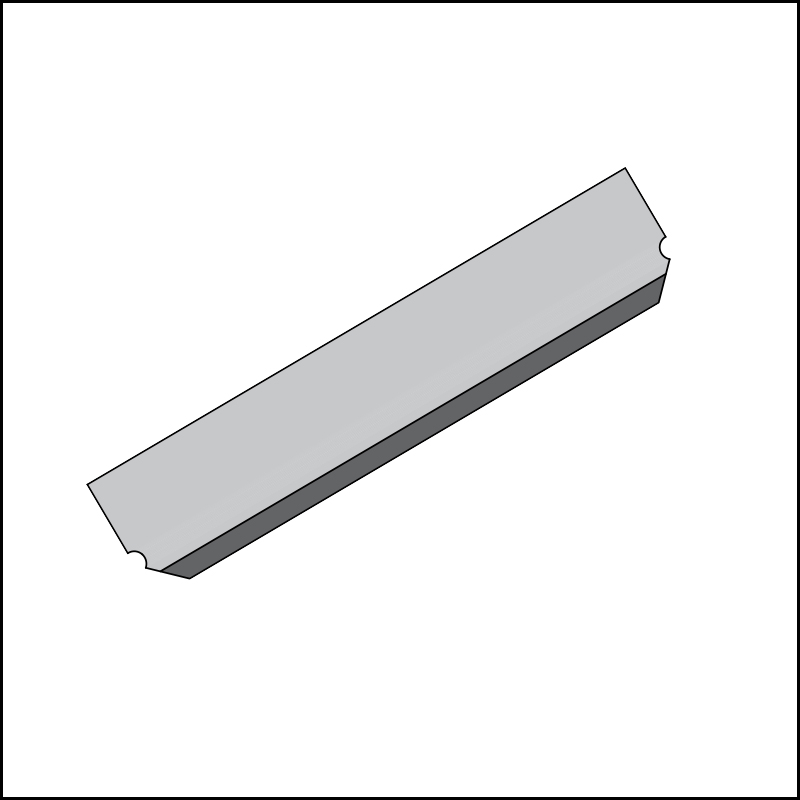

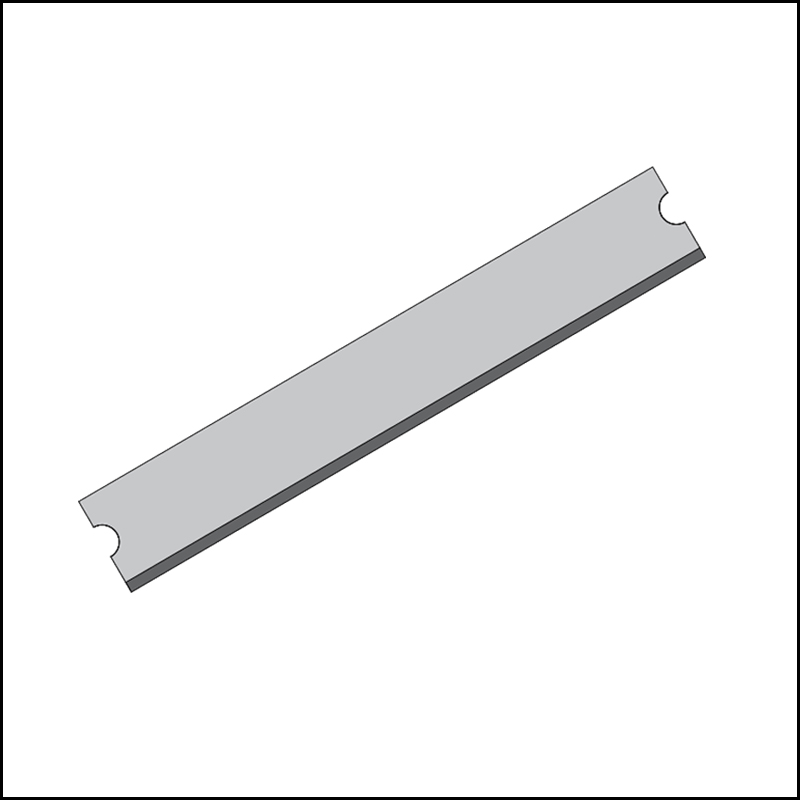

In the micro-scale world of modern manufacturing, where tolerances are measured in microns and material integrity determines product viability, thin film 3-hole blades like Meiren Technology’s MRT-A43-22-0.2 represent a quantum leap in cutting technology. Engineered for applications demanding surgical precision, these ultra-thin hard metal blades (0.1–0.4 mm thickness) are transforming industries where traditional cutting tools fail. Their trifecta of holes isn’t merely a design feature—it’s a functional breakthrough enabling stability, custom alignment, and material flow control impossible with solid blades

The Anatomy of Precision: Why Design Matters

The MRT-A43-22-0.2 foil blade exemplifies how microscopic engineering solves macroscopic challenges:

Material Science: Crafted from hard metals (likely tungsten carbide or cobalt-bonded composites), these blades achieve Vickers hardness values exceeding 1,800 HV. This grants exceptional wear resistance when slicing abrasive materials like carbon fiber prepregs or ceramic-coated films

Dimensional Mastery: At 43 mm length and 22 mm width, the blade optimizes surface contact while minimizing deflection. The sub-0.4 mm thickness enables clean shearing of materials prone to micro-fractures, such as OLED layers or lithium-ion battery electrodes

Triple-Hole Architecture: Strategically placed holes allow for:

Vibration Damping: Reducing harmonic resonance during high-speed cutting.

Modular Alignment: Enabling pin-based calibration for multi-blade configurations.

Debris Management: Preventing adhesive buildup in sticky-material cutting

Industry Transformations: Where Ultra-Thin Blades Excel

1. Energy Storage & Battery Manufacturing

Lithium-ion battery production demands flawless electrode cutting. Traditional blades cause burring or delamination in anode/cathode foils (often 6–20 μm thick), reducing cell efficiency. Meiren’s blades achieve:

Zero-Tolerance Cutting: Maintaining ±0.05 mm accuracy in electrode slitting.

Extended Lifespan: 3× longer service life than steel blades when processing graphite-coated copper foil.

Contamination Control: Hard metals generate fewer metallic particulates, critical for cell purity

Impact: Battery gigafactories report 12% higher electrode yield and 15% reduced blade replacement downtime.

2. Flexible Electronics & Displays

OLED and quantum dot layers require scribing without micro-cracks. The blade’s 0.1 mm variant enables:

Curved Cut Precision: Essential for foldable screen components.

Multilayer Stack Processing: Cleanly separating PET/ITO/phosphor laminates <5 μm thick.

Electrostatic Discharge (ESD) Safety: Hard metals minimize spark risks near sensitive circuits

3. Medical Device Fabrication

Bioabsorbable Implants: Cutting poly-L-lactic acid (PLLA) vascular scaffolds without polymer deformation.

Diagnostic Strips: High-speed perforation of nitrocellulose membranes in lateral flow assays.

Surgical Foils: Shaping titanium meshes for cranial implants with edge uniformity <2 μm roughness

4. Sustainable Packaging

Biodegradable Barrier Films: Precisely slicing PLA-based composites without melt zones.

Recyclable Aluminum Laminate Separation: Delaminating Tetra Pak-style materials for component recycling

Customization: The Competitive Edge

Meiren’s "one-stop non-standard customization" service addresses niche demands impossible for off-the-shelf blades

Geometry Optimization: Adjusting hole positions for specific die-cutting machinery.

Coating Integration: Adding diamond-like carbon (DLC) coatings for cutting silicon wafers.

ESD-Safe Variants: Incorporating conductive phases for explosive-environment safety.

Size Scaling: Prototyping blades down to 10×10 mm for microfluidic chip production.

A Shanghai battery material supplier reduced waste by 28% after switching to hole-position-optimized blades for their Korean-made slitters.

The Future: Smart Blades and AI-Driven Wear Prediction

Next-generation iterations are incorporating:

Embedded Sensors: IoT-enabled blades monitoring vibration spectra to predict failure.

Adaptive-Geometry Blades: Shape-memory alloys adjusting hole alignment in real-time.

Nanostructured Edges: Self-sharpening nanocrystalline coatings extending operational life by 400%

Precision as a Strategic Asset

In sectors where micron-scale imperfections cost millions, Meiren’s thin film blades transcend mere tools—they are enablers of impossibility. As flexible electronics, solid-state batteries, and implantable medical devices redefine technological frontiers, the silent revolution of the 43×22×0.2 mm blade proves that manufacturing’s future isn’t just built—it’s precisely excised.